Fitwel Industries LLP is an ISO enterprise, guarantee you quality at every step. We are a Manufacturers, Suppliers and Exporter of Nickel Alloy Long Radius Bend that are formed from the purest, wrought Nickel, giving the exceptional qualities like ductility, unaltered mechanical properties under a series of temperature changes and exemplary power to tolerate and ward off effects of a diverse range of corrosives. Our Nickel UNS N02200 Long Radius Bend have a larger radius compared to a Nickel 200/201 1.5D Pipe Bend, instantly making them more favourable to use to aid a variety of piping systems in the food processing industry. Our UNS N02201 Nickel U-Long Radius Bend vary only in Carbon quantity, they give an unmatched resistance to caustic alkalies and reducing chemicals at soap manufacturing and salt production units. For every customer need, we aim to serve premium products, customer-centric service, a quick product delivery strategy and complete assistance. We go the extra mile to form a bond of trust with our clients.

Resisting hydroxides, and hydrochloric and sulphuric acids at modest temperatures, our WNR 2.4066 / 2.4068 Seamless Nickel Long Radius Bend have good thermal conductivity. Also We offer wide range of Nickel Alloy ASTM B366 200 Long Radius Bend such as Nickel 201 Long Radius Bend, Nickel Alloy 201 Piggable Bend, 200 Nickel Hot Induction Bend, 201 Nickel Alloy Seamless Pipe Bend, Alloy 200 Welded Pipe Bend, Nickel 201 U Pipe Bend, High Nickel Alloy 200 J Pipe Bend, Nickel 201 Mitered Pipe Bend, Nickel 200 3D Pipe Bend, Monel Long Radius Bend, Inconel Long Radius Bend, Incoloy Long Radius Bend, Copper Nickel Long Radius Bend etc.

The Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend/elbow refers to the outer diameter of the tube whose radius of curvature is equal to 1.5 times, that is, R = 1.5D. It does not represent the inner diameter of the pipe or the outer diameter of the pipe. It is a nominal size designed and used.

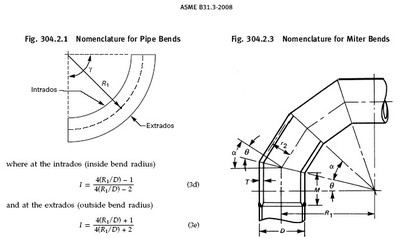

Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend Manufacturers in India is a generic term for any offset or change of direction in the piping. It is a vague term that also includes elbows. Bends are generally made or fabricated as per the need of the piping; however elbows are pre-fabricated and standard, and are available off the shelf. Bends are never sharp corners but elbows are. Pipe bending techniques have constraint as to how much material thinning can be allowed to safely contain the pressure of the fluid to be contained. In bends as the pipe is bent and there is no welding involved, there is less pipe friction and flow is smoother.

The Long Radius Bend should be as per the standard of ANSI/ASME B16.49 which did not specific the bending radius and angle, the regular pipe bend radius are 2.5D, 3D, 5D, 7D or 8D, but it can be any other bending radius according to the design need, and bending angle can be in any degree, 5 ,10 ,15, 90 degree or any other. People said “All bends are elbows but all elbows are not bend”, it is not true. Actually “All elbows are Long Radius Bend but not all bends are elbows” is more reasonable.

The most basic difference of them is the elbow relatively short than bend, R = 1D to 2 D is elbow More than 2D is bend. In the production process, cold bends can use Bending Machine to bend by ready-made straight bend. One-time completed also don’t need second corrosion. But elbow need manufacturers make to order, to do anti-corrosion, order cycle is long. Elbow price is higher than bend. But cost performance is much higher than bend. It is well-known that bend do not have anticorrosive processing is easy damaged, but the price is cheap so are used very much in some demand which not very high engineering.

In the west-east gas transmission of course, cold bends cost is low. elbow need manufacturers make to order, needs corrosion, order cycle is long,but cold bends can use ready-made straight bend by Bending Machine to bend. One-time completed also don’t need second corrosion. The cold bend construction technology need follow oil standard .west-east gas transmission have the enterprise standard,but we can use either elbow nor bend in open area. Sunny Steel Enterprise warn broad customers betweenness elbow and bend performance price is differ ,please carefully choose after consider it.

Size : Seamless Long Radius Bend (1/2″ – 24″), ERW / Welded / Fabricated Long Radius Bend (2″ – 36″)

Standards : ASME / ANSI - B 16.9, ASTM A403 - ASME SA403, ASME B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

Thickness : 2-40 mm / SCh4, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / ERW / Welded / Fabricated

Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Form : Piggable Bend, Hot Bend, Long Radius Bend, Induction Bend

Nickel Alloy Buttweld Long Radius Bend :

ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe.

| Buttweld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend | Butt Weld Pipe Caps |

| ASME B16.9 Butt weld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend | Steel Cap Pipe Fittings |

| Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend Suppliers | SS Buttweld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bends Fitting |

| ANSI B16.9 Buttweld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend Dealer | ASME B16.28 Buttweld Pipe Cap Exporter |

| Welded Butt weld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bends Stockholder | Seamless Butt weld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend Distributors |

ASME B16.9 Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Buttweld Long Radius Bend are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of buttweld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend through a worldwide network of stock-keeping branches. These buttweld elbows is used in various industries like:

We are renowned & most acclaimed Manufacturer, Suppliers & Exporter And Stockist of Buttweld Long Radius Bend in Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201.

For More Information About Buttweld Copper Nickel, Inconel, Monel 400, Alloy 20, Nickel Alloy 200/201 Long Radius Bend Please Call 91-22-2382 9256 or Send an Email to sales@fitwelindia.com