Fitwel Industries LLP manufactures of Stainless Steel Flanges of different shapes and sizes and with different specifications as per the customers’ requirements. We are the world leader in Stainless Steel Forged Flanges & Stainless Steel Socket Weld Fittings. We cater to the huge global demand of our customers who are spread across 6 continents and around 120 countries. Our flanges manufacturer in mumbai are reputed and well known across the globe for their reliability and quality. We treat our customers as our partners by providing them with our products and solutions. And this ethos is displayed in not only our thoughts but also in our actions.

We offer a comprehensive range of heavy-duty, general-purpose industrial stainless steel flanges compatible with an array of stainless steel each PED Approved Flanges sizes, for use up to a maximum pressure of class 150psi. Our PED Certified Stainless steel flanges are heavier than most other brands, with a fuller wall thickness they offer a longer life cycle than similar products. Our flanges manufacturer in India division encompasses an integrated forge shop which manufacturers all types of pipe fittings i.e. flanges, butt welding fittings in various specifications (ASME/ ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, UNI, etc) as well as forged bars. We produce flanges in the size range from ½” to 40”. We have an established and stringent quality system with more than 90 approvals and certifications in accordance with various specific requirements and applications. These approvals and certifications help us supply our Stainless Steel Flanges Manufacturers in India to major end-users across a diverse list of industries.

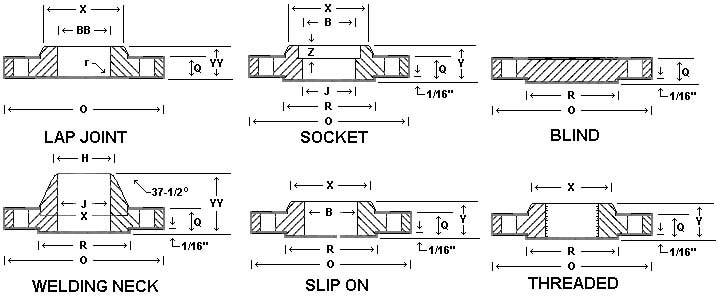

We are Stainless Steel Flanges manufacturer in India since the year 1987. In our product range, we manufacture WNRF, SORF, SWRF, BLRF, RTJ Flanges in all pressure ratings and ANSI/ ASME standards. Check class 150 Stainless Steel Flanges dimensions and SS flange weight chart in kg before buying flange material in India. We are specialists in Stainless Steel flanges pn16, Pn10, Pn40. View class 300 Stainless Steel Flanges pressure rating. Call our experts to know more about SS flanges tabled and table e. also refer bs en 1092-2 flange dimensions. Also We offer wide range of Stainless Steel ASTM A182 Flanges such as SS Slip On Flanges, SS Weld Neck Flanges, SS Socket Weld Flanges, SS Blind Flanges, SS Orifice Flanges, SS Spectacle Blind Flanges, SS Screwed/Threaded Flanges, SS Reducing Flanges, SS Ring Type Joint Flanges (RTJ) etc.

Fitwel Industries LLP is focusing on offering these flanges that fully satisfy the exact requirements of our esteem customer. Before dispatching these flanges for delivery, we ensure that each flange is tested under stringent conditions to provide higher efficiency. We own a highly experienced quality control expert team that performs several tests on SS Flanges to check different characteristics and parameters. The testing is carried out throughout the production process under strict observations. We arrange third-party inspections for our clients. We have a large inventory of SS Flanges which is stored in our highly secured warehouse. Our Flanges manufacturer in Pune can be stored for a longer duration in our warehouse, and from here urgent demands of industries across the globe can be completed.

Stainless Steel Flanges manufacturer of different stainless steel materials. There are different grades to the stainless steel depending on the material composition and the mechanical properties vary. Fitwel Industries LLP is a leading manufacturer and supplier of these flanges. Stainless Steel Flange is a forged, or it is called a cast ring which is designed to connect different sections of the pipe or any other machinery that requires an intermediate connecting point. These flanges are in massive demand in the market because of their tensile strength and surface finishing.

A Stainless Steel Class 150 flange Mumbai is a method of connecting pipes, valves, pumps, and other equipment to form a piping system. It also provides easy access for cleaning, inspection, or modification. Stainless Steel Flanges are usually welded or screwed. Flanged joints are made by bolting together two Flanges with a gasket between them to provide a seal.

Our manufacturing facilities are well equipped to manufacture various types of flanges namely:

These are easily fitted and welded into different pipes. Slip on pipe flange is slipped over the Pipe and then welded both inside and outside to provide sufficient strength and prevent leakage. These flanges are ideal for lower pressure applications. This Flange is used in preference to Weld Necks by many users because of its lower cost and the fact that less accuracy is required when cutting pipe to length.

Weld Neck flanges have a long tapered hub and are often used for high pressure applications. These flanges are designed to be joined to a Piping system by Bun Welding. The Neck, or Hub, transmits stresses to the Pipe, reducing stress concentrations at the base of the Flange. The gradual transition of thickness from the base of the Hub to the wall thickness at the Bun Weld, provides important reinforcement of the Flange. The bore of the flange matches the bore of the Pipe, reducing turbulence and erosion. These flanges are ideal for extreme fluctuations of temperature and in environments where there may be high pressure or high temperature being dealt with.

A Blind flange is a round plate that has all of the relevant boltholes but no centre hole, and because of this feature this flange is used to close off the ends of the piping system and pressure vessel openings. It also permits easy access to vessels or Piping systems for inspection purposes.

These flanges are attached by inserting the pipe into the socket end. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. Socket-weld pipe flanges are mainly used for smaller sizes of high-pressure pipes.

Threaded flanges are similar to slip-on pipe flanges except the bore of threaded pipe flange has tapered threads. These flanges are ideal for relatively low pressure piping systems. Threaded flanges are used with pipes that have external threads. The benefit of these pipe flanges is that they can be attached without welding.

Lap Joint Flanges slide over the pipe and are most commonly used with Stub End Fittings. A pipe is typically welded to the Stub End and the Lap Joint pipe flange is free to rotate around the stub end. Lap Joint pipe flanges are often used for applications that require frequent dismantling. Threaded pipe flanges are often used for small diameter, high-pressure requirements.

Orifice Flanges are used instead of standard pipe flanges when an orifice plate or flow nozzle must be installed. Pairs of pressure tappings are machined into the orifice flange, making seperate orifice carriers or tappings in the pipe wall necessary.

In addition to these we also manufacture Orifice Flange, Stub-end fittings, plate flanges, backup flanges, Beveled ID flanges, and Reducing flanges.

Our Stainless Steel Flanges are having some great features.

| A182 Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Stainless Steel Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| SS Grade Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ASTM A182 Stainless Steel Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| ASME SA 182 Flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| ASME SA182 Stainless Steel Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| A182 Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ASTM A182 Stainless Steel Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| ASME SA182M SS Flange Production technique | Forged, Heat treated and machined |

| A182 Grade Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| ASME A182 SS Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| ASTM A182 SS Flange Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| SS Flange Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of Stainless Steel ASTM A182 Flange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| ASME SA182M Stainless Steel Flange Uses & application | Bitumen upgraders. Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

| SS EN 1092-1 Flange Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi & Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| Flanges | Size | |

| ASTM A182 SS 304 Slip-On Flanges | ASTM A182 SS 304 Threaded Flanges | Sizes 1/8″ – 36″ Raised Face or Flat Face |

| ASTM A182 SS 304 Weld Neck Flanges | ASTM A182 SS 304 Socket Weld Flanges | |

| ASTM A182 SS 304 Blind Flanges | ASTM A182 SS 304 Reducing Flanges | |

| ASTM A182 SS 304 Lap Joint Flanges | ASTM A182 SS 304 Plate Flanges | |

| ASTM A182 SS 304 Orifice Flanges | ASTM A182 SS 304 Forged Flanges | |

| ASTM A182 SS 304 Ring Type Joint Flanges | ASTM A182 SS 304 Square Flanges | |

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | - | 8 – 11 | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

ASTM A182 Stainless Steel Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of ASTM A182 Stainless Steel Flanges through a worldwide network of stock-keeping branches. These Stainless Steel Flangeso is use in various industries like :

We are renowned & most acclaimed Source, Stockist, Distribution, Manufacturer, Suppliers, Stockholder, Traders, Wholesaler, Dealer, Distributor, Importer & Exporter, Fabricator, Stockist of Stainless Steel Flanges.

For More Information About Flanges Please Call 9987994248 or Send an Email to sales@fitwelindia.com